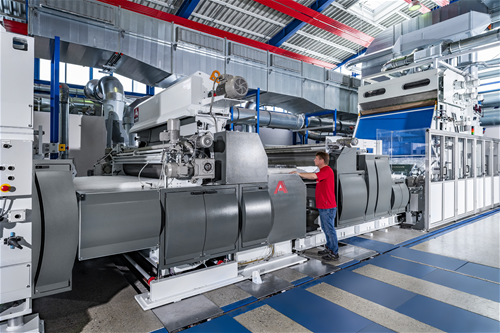

AUTEFA Solutions Airlay random card K 12, in combination with Stylus Needle Loom or HiPerTherm Oven, meet all customer requirements for maximum productivity and constant high quality. Suitable for all kinds of bonding processes such as thermal-, chemical- or needle-bonding. Airlay line solutions distinguish itself through maximum product quality, economical production and reliability. With worldwide over 500 systems sold, customers taking advantage of the long-standing experience in carding and card feeding technology of F.O.R. and the worldwide acknowledged know-how in aerodynamic web forming of Fehrer K 12. In the construction, residential and automotive market, efficient thermal and acoustic insulation materials are key factors that contribute to energy saving and to the reduction of natural resources consumption. The increased opening capabilities distinguish itself for a wide variety of different fibers. The process offers the special advantages when it comes to lighter weights and high loft fabrics. The FUTURA design enables easy opening and quick access for cleaning and maintenance. The various line components are mounted on a linear guiding system. Due to the modular structure of the individual components, it allows a modular configuration of the machine, tailored to customer requirements. Completed with Needle Punching Machines Stylus and Thermobonding Oven HiPerTherm, AUTEFA Solutions provides aerodynamic web forming lines out of one hand.